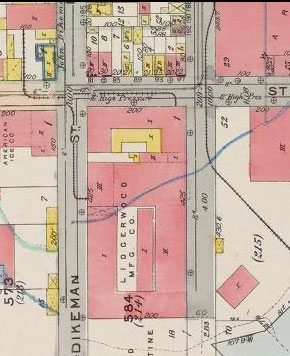

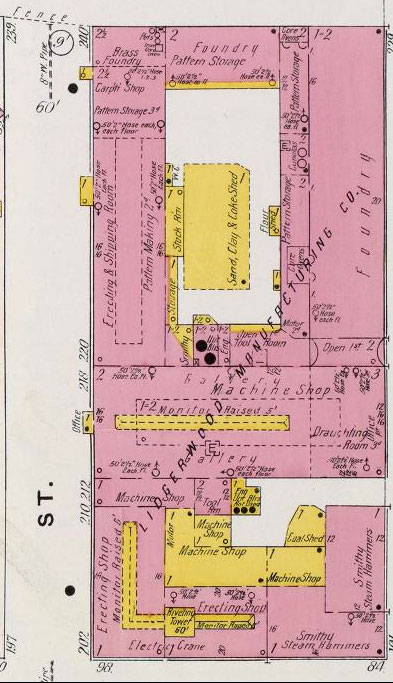

Ferris between Coffey (formerly Partition) and Dikeman Streets

Lidgerwood Manufacturing was (is) a world famous maker of hoists and boilers. It manufacturing works were located on Ferris street in Red Hook Brooklyn from at least 1882 until 1927. They had offices at 96 Liberty Street, Manhattan.

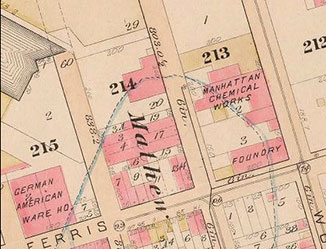

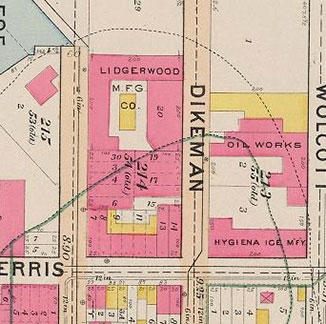

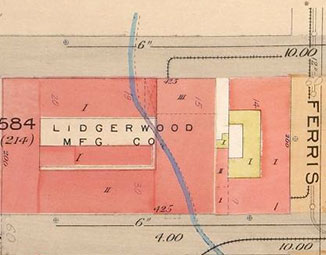

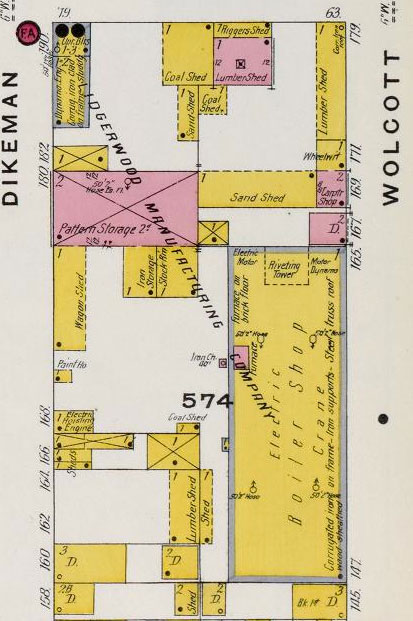

Lidgerwood Manufacturing (or Iron Works) was not designated as such on the 1880 or 1886 Ward 12 maps. Later maps show that it was located at the intersections of Dikeman, Coffey (formerly Partition) and Ferris. The 1886 map does show a large brick building on the north west corner of Partition and Ferris but does not identify the structure. Lidgerwood Manufacturing was show between Dikeman and Coffey (formerly Partition street) on a 1898-99 map of Ward 12. See maps below.Lidgerwood Manufacturing Co., manufacturer of steam and electric hoists, boilers and suspension cableways, was founded in 1873 in Brooklyn. The company employed 800 men in 1883 when it was planning a move to Newark, New Jersey. The move was motivated in part to obtain more space and in part because there was "too much government" in Brooklyn. (American machinist, Volume 26, 1883)

They must have changed their minds because in in 1883 they had their "new shops" at the corner of Dikeman and Ferris " in good working order". They were working 100 men during the day and 25 at night. The United States Electric company supplied lights for the night workers.

The Preservation Plan for Red Hook lists Lidgerwood Manufacturing Co. 84 Ferris St, Year: 1882, Architect: J.V. Beekman*, Original use: Manufacture of machinery. The buildings address is still 84 Ferris Street.

*John V. Beekman was a member of the firm and a long term supervisor at the works.1892: "the company have purchased twenty lots opposite their present works, where additional shops, storage etc will be erected. The present works in South Brooklyn cover an entire block and are conceded to be the finest of their kind in the United States".

Lidgerwood in the press

1874: Lidgerwood Manufacturing Co at 165 Pearl Street New York was advertising hoisting engines and mining machinery.1876: No. 159,066. John V. Beekman, of Brooklyn, N.Y., assignor to the Lidgerwood Manufacturing Company, of New York city, for "Rotary engines." - Application filed 15th September, 18/4. (The Commissioners of Patents' Journal By Great Britain. Patent Office)

1880: An 1880 map shows an unlabeled brick building on the land later occupied by Lidgerwood. It does not have the footprint of the building that still stands on the spot today. It would appear that the building that stands there now was built circa 1882 as indicated by the 1882 building permit listed in the American Architect and Architecture.

1882: Brooklyn Building Permits Dikeman St. s.s. between Ferris and Partition sts one story black smith shop cost $3,000 owner, Lidgerwood Manufacturing co 96 Liberty st, New York architect J. V. Beekman builders, P. Carlin and sons and J Martin (American Architect and Architecture, Volume 12)

1884: Lidgerwood Manufacturing had a fire at their factory in Brooklyn in 1884 and lost a portion of their patterns (wooden models or templates of the various machine parts).

"By the fire at the foundry in South Brooklyn, N. Y., on the 28th of February last, the Lidgerwood Manufacturing Company lost only a small portion of the large amount of patterns belonging to them. The various newspapers in New York and vicinity reported the loss from $50,000 to $70,000, whereas the total loss did not exceed $6,000, the fire occurring in a room where, fortunately, very few patterns had been stored. The company lost no time in making new patterns, commencing the following day with a large force of pattern-makers, and have at this writing made such progress that they will very shortly have new patterns equal to those which were destroyed. By the wise system adopted by this company of always keeping on hand a number of castings of the various hoisting engines manufactured by them, no delay has been occasioned in filling orders or building engines for stock."(The Manufacturer and Builder, Volume 16 edited by Peter Henri Vander Weyde, William Henry Wahl)

1884: Lidgerwood Manufacturint Co., steam engine makers ft* Elizabeth street Brooklyn (J.A. Berly's Universal Electrical Directory and Advertiser By Jules Albert Berly)

*foot

1885: Thomas Wright age 29, an employee of the Lidgerwood Manufacturing company in Red Hook died when he was oiling a machine and became caught in the belting.

1886: In July 1886 Mr. W. V. Lidgerwood, a manufacturer in South Brooklyn, launched a beautiful, $20,000, steam pleasure yacht the Speedwell from the Erie Basin. The Lidgerwood family lived on Speedwell Ave in Morristown, N. J.

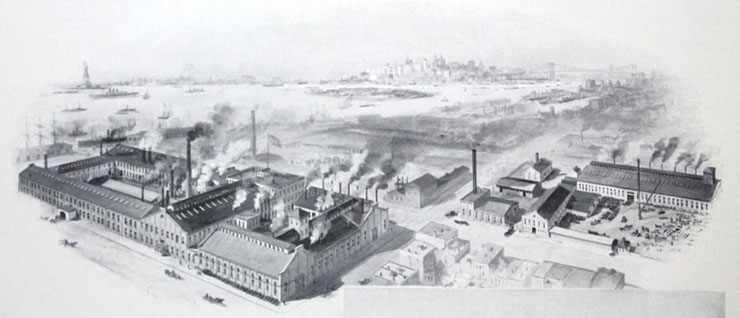

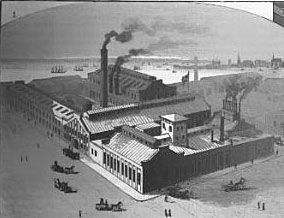

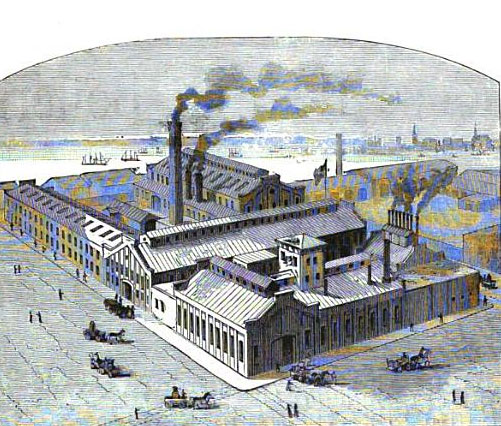

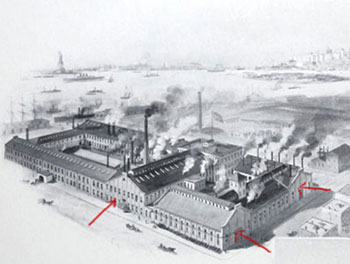

1888: June 2, 1888 (See illustrations below)

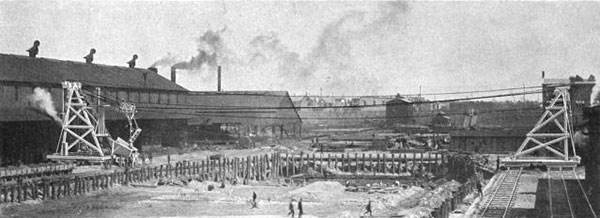

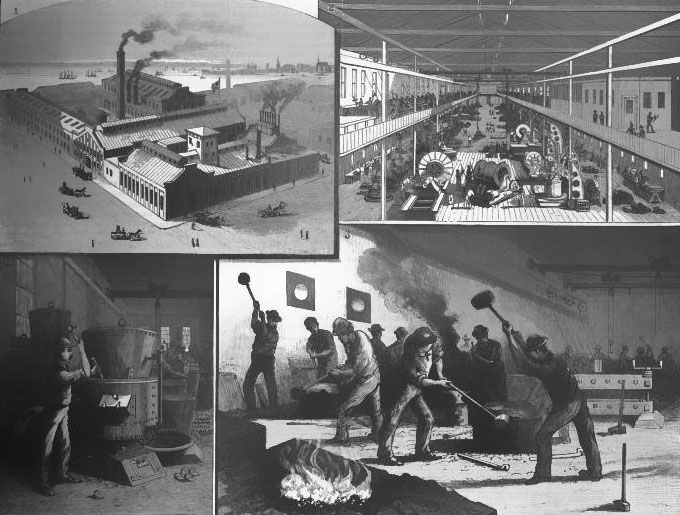

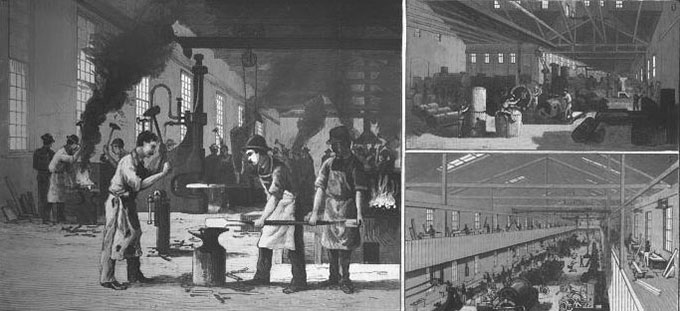

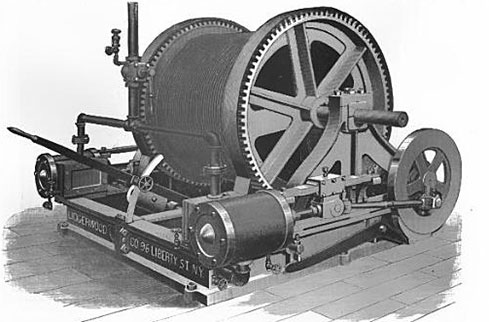

THE LIDGERWOOD MANUFACTURING CO. HOISTING ENGINES AND BOILERS - THE GORTON HEATER.1889: Lidgerwood Manufacturing proposed to add a one story frame extension 88.4x24.5 to shop on Dikeman, Ferris and Partition cost $550. (BE)In the illustrations on our first page we have endeavored to bring before the mind a correct idea of the plant, and the methods of prosecuting the work, in one of the largest and best equipped modern establishments especially devoted to the manufacture of hoisting engines and boilers.

The works of the Lidgerwood Manufacturing Company, which we take as a type, are near the Atlantic Basin, at the foot of Dikeman Street, Brooklyn. The main machine shop is 75 by 200 feet in size, and, with its gallery and two wings, affords a floor space of 28,750 square feet. The erecting shop covers a ground space of 50 by 228 feet, and with its gallery affords 17,500 square feet of floor room. The boiler shop is 50 by 290 feet, the blacksmith shop 45 by 90 feet, the Gorton heater shop 25 by 100 feet, and the storage shop 45 by 100 feet. Power is supplied by two engines, connected, but which may be readily disconnected, when either one will afford sufficient power for the entire establishment. All of the departments are completely fitted out with powerful traveling cranes, and the equipment in lathes and boring and turning machines of the latest patterns is designed to more than meet every possible demand. In every branch of the business, attention has been constantly directed to securing uniformity as well as perfection of work through the employment of machinery ; and in milling machines there are several of novel construction, especially designed for the work of the company, who have made something of an innovation on ordinary machine practice in the extent to which they carry the work of machine milling.

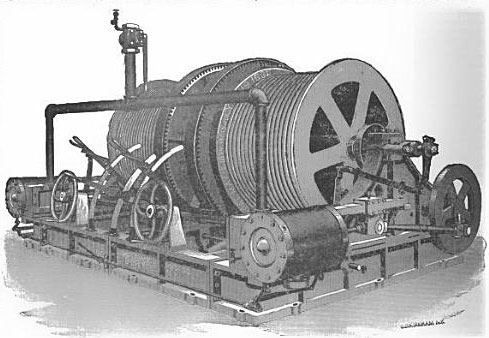

The engines made by the company present too great a variety for us to mention them all in detail, but their single and double cylinder friction drum portable hoisting engines, with the latest improvements, constitute a representative type of a large part of their business. In the latest patterns of these engines, embodying the results of many year's experience, especial care has been taken to have them simple in design and construction, and well proportioned throughout in accordance with their cylinder power. The cylinders are of extra quality charcoal iron, the steam and exhaust ports being of ample size and designed for high speed, with D slide valve, the valve and valve seat having a scraped fit. The valve and piston rods are of steel, and the crosshead is of the locomotive hanging type, fitted with composition gibs having extra large wearing surfaces and easily adjusted to take up wear. The connecting rod is of best Ulster iron, and the drum and crank shafts are of the best quality of wrought iron, and calculated to be of ample strength for any possible requirement. The crank wheel is counterbalanced, and is forced on the crank shaft by a special press. The bearings are large and fitted with anti-friction metal. A winch head is placed on the outer end of the drum shaft, and a band fly wheel on the crank shaft, for pumping, sawing. etc.

The friction drums of these engines have many improvements for which patents are held and owned by the company. The frictional hold is effected by the engagement of segments of hard wood, bolted on the inner surface of a spur wheel, to make a hollow inverted double cone, with corresponding coneshaped flanges at one end of the drum. The spur wheel is actuated by a pinion on the crank shaft, and is ordinarily in constant motion. The drum is loose on its shaft, on which it has long bearings, and is free to revolve without sensible resistance, but the coneshaped flange at one end of the drum is thrown into friction contact with the wood-lined spur wheel by a slight lateral motion of the drum, effected by means of a lever, screw, pin, cross key, and collar, and released by means of a spiral spring interposed between the friction surfaces. The great power afforded by this construction is obvious, being such that a very slight pressure will hold the drum against any load the engine can hoist. The end thrust caused by the lateral movement of the drum shaft is taken up by a thrust hearing and screw collar. The friction wood is secured to the inner surface of the spur wheel by bolts and nuts in such way that it can be always kept tight without trouble.

The drums are extremely durable, having been in constant use for years without requiring renewal, and the entire machine leaves nothing to desire in the quickness of its operation and the ease with which it can be managed. This is particularly exemplified in pile driving, when compared with the work done by any clutch and brake engine. The rope is made fast to the hammer, and passes up over the sheave and down around the drum. When the hammer is raised to the desired height, the drum is released, the rope then overhauling the freely revolving drum as the hammer falls, it being entirely within the discretion of the operator, without a moment's delay, to give either short quick blows, or long and heavy ones, from the entire height of the pile-driving frame. This class of engine has now largely superseded all others for such work, hammers of twice the weight formerly employed being now commonly used, without damaging the heads or splitting the piles, and enabling the operator to give many more equally powerful blows in a minute. The quickness with which piles are driven thereby is generally very surprising to foreign workmen, and the export demand for these engines is large and growing.

In general hoisting work, as the weight is raised to the desired height, the moving of the lever and the operation of the spring loosens the hold of the friction drum, as required for ordinary lowering purposes, but foot brakes are preferably to be used therefor, as saving wear on the friction drum, and allowing the use of the engine for other purposes when a weight is to be held. These foot brakes can at any time be readily applied to an engine not having them, and some of the styles of engines are fitted with ratchets and pawls which may be thrown in and left with a load suspended.

The double cylinder engines are similar to those with single cylinders, except that they have the special feature of having no centers, the engines being connected at an angle of 90°, thus rendering them much easier to start and handle, single cylinder engines being sometimes caught on centers in handling heavy work. Double friction drum engines, with either single or double cylinders and reversible link motion, are supplied in various patterns specially adapted for quarrying, dock and bridge building, etc., whereby two derricks can be operated, or one drum can hoist a pile in pile driving, while the other handles the hammer. Double drum and double end hoisting engines are made in several varieties calculated to run at different speeds, and a style of portable hoisting and power engine is made to be housed, if desired, when, but for its larger wheels, it somewhat resembles a small dummy engine for street railway use.

Perhaps the most efficient machine ever built for mining operations is the large mining and tail rope hoisting engine made by the company, and specially adapted for double track inclines or double shafts in mines. It has double friction drum and brake and reversible link motion, both drums being loose and independent of each other, so that they may be thrown in and out of gear with the engines in motion, or one drum may be lowering while the other is hoisting, or both may be thrown into gear and the engine used as a regular reversible engine, one load being hoisted while the empty cage is being lowered. This is done with the minimum of friction and wear on the engines, and the great desirability of such independence of drum action, particularly on inclines or in mine shafts, will be at once obvione to all engineers and workmen experienced in mining operations.

Space will not admit, however, of such reference as would do justice to the great variety of engines made by the company. Work for which they have a regular demand they keep always in stock, their manufacture being carried on according to the duplicate part system, from complete sets of gauges and templates, which insures absolute accuracy. Instead, therefore, of building each engine separately, they are always ready, on receipt of an order, to send the parts to the erecting shop and set up the particular engine called for, after which the engine is thoroughly tested, being set up and run with steam on before being shipped. This system not only reduces the cost of production, while necessarily calling for the highest degree of accuracy, but it enables a user of these engines to obtain at any time, without delay, any special part of an engine which may give out, from wear or accident. The standard character of these engines has been recognized by different departments of the United States government, in their specifications for contractors, in which, in many cases, it is stipulated that engines furnished shall be equal to those of the Lidgerwood company. They have been on the market now some eight years, and there are over 4,500 of them in use, being employed in every part of the world.

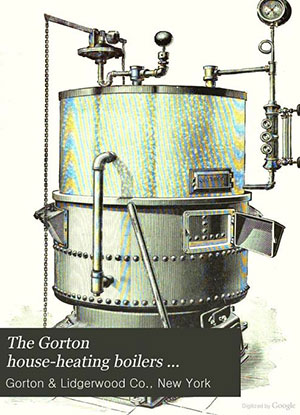

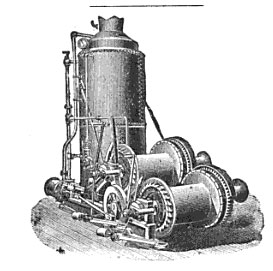

The manufacture of boilers specially adapted for these various engines constitutes an important portion of the business of the company, as they make also marine boilers of all kinds, horizontal return tubular boilers, stationary and portable locomotive boilers, upright tubular boilers, and any kind of work in this class which may be called for. The shells, unless otherwise ordered, are made of CH No. 1 shell iron, of 50,000 lb. tensile strength, and the tube heads of the best flange iron, all of brands tested and known to be reliable, steel being used in place of iron when ordered. All of the boilers are hydraulic riveted, every rivet being subjected to exactly thirty-five tons pressure. The bracing and staying is of ample strength to allow a large factor of safety. The edges of sheets are planed off true and smooth, and the seams are thoroughly calked inside and outside. The tube heads are flanged on formers specially made for the purpose, the tube holes being drilled to size and the tubes carefully fitted, being usually driven in with a maul and then expanded. The fittings are complete, strong, and substantial, of good design, being made by special tools. The tests include a practical steam test to the guaranteed working pressure of 100 pounds, and a hydrostatic test to a pressure of 160 pounds, and every boiler must be found perfect under such pressure before being sent out. As relating to a branch house of the Lidgerwood Manufacturing Company, we illustrate in one of our first page views the large Gorton heater shop of the Gorton 85 Lidgerwood Company. These heaters have been many years before the public, and have had a large sale, which, with the extensive facilities of the company for their manufacture, afford the best evidence of their high character. These house-heating boilers are for private residences, schools, public buildings, etc., and are unlike any other boiler for such purposes. They combine improvements attained through many years practical experience in satisfying the demands of a large trade. They are side feed boilers, built on the plan of an upright tubular boiler, and are self-feeding as well as surface burning, being adapted for use either way. The coal reservoir is between the lower outside surface of the boiler and the water leg, and the tubes are directly above the fire, the heat passing up through them to the top and thence down on the outside between the boiler and jacket to the smoke pipe in the back. The boiler is designed to generate steam in the most economical and effective manner, the tubes being placed as thickly as will admit of proper circulation, and its evaporative efficiency is calculated as fully equal to that of the return tubular boiler. The coal reservoir is designed to hold sufficient coal to last from twelve to twenty-four hours without refilling, and the grate is low in the center, so that the coal will gradually feed down from the outer surface as it is needed, and distribute itself at a uniform depth over the surface of the grate, the fire being always directly under the tubes. The grate is of the shaking and dumping type, its outer or main part resting on ball bearings, so that it can be easily shaken, and the center part being independent and arranged to swing to one side for removing clinkers or dumping the fire. This boiler can be used with efficiency and economy for circulating hot water, as well as for making steam.

The general offices and salesrooms of the company are at No. 96 Liberty Street, New York, and No. 159 Friend Street, Boston.

(Scientific American)

1889: In 1889 Lidgerwood Manufacturing bought a property on Dikeman near Ferris with plans to build a one story brick building 229. x 50, to cost $20,500. 1889: The "works for the Lidgerwood Manufacturing Company were located at

"the foot of Dikeman Street, South Brooklyn being practically on the water front, and are midway between the Atlantic and Erie Basins. The main machinery shop is-75 by 200 feet in size, and with its gallery which extends the entire length on either side, and two wings, affords a floor space of 28,750 square feet. The erecting shop covers a ground space of 50 by 200 feet. It also has a gallery and altogether affords 17,500 square feet of floor room. The boiler shop is 50 by 290 feet, and the blacksmith shop, 45 by 90 feet while the storage shop measures 45 by 100 feet. Power is supplied by two engines, connected, but which may be readily disconnected, when either one is capable of supplying sufficient power for the entire establishment. All the departments are completely fitted out with powerful traveling cranes, and the equipment, in lathes and boring and turning machines of the latest pattern, is designed to more than meet every possible demand. In every branch of the business, attention has been constantly directed to securing uniformity as well as perfection of work, through the employment of machinery."1890: The Lidgerwood Manufacturing Co. of Chicago, Boston and New York opened a branch "house" in Portland Oregon.Improved Hoisting-Engines for Mines. (The Colliery Engineer ..., Volume 9)

The Lidgerwood Manufacturing Company, of Chicago, Boston and New York, have just opened a branch house at Portland, Oregon, in charge of Mr. Joseph M. Arthur, which will be located at Nos. 1,3, 5 and 7 North First street, that city. Here a stock of all sizes of their famous hoisting engines will be carried, and customers in that locality will now be enabled to deal direct with the manufacturers. Under the able direction of Mr. Arthur this branch will grow to mammoth proportions. Those dealing with this gentlemen may be sure of courteous treatment and prompt and careful attention to their wants. The demand for Lidgerwood hoisting engines for all hoisting purposss continues at high water mark.(The American Engineer, Volumes 19-20)

1891: In May 1891 the company was proposing to "add a story of brick to machine shops on Dykeman street, near Ferris, and make other alterations, at a cost of $2,000."

1891: Engineering News the Linderwood Manufacturing co of New York, Chicago and Boston are enlarging their present works in Brooklyn, N.Y. and have just opened a branch office in Pittsburg. (The American Engineer, Volumes 21-22)

1892:

The Lidgerwood Manufacturing Company, with headquarters at 96 Liberty street, New York City, have established a branch house in St. Louis for the sale of their standard hoisting engines, at 610 North 4th street, and 609 North 3rd street, under the management of M. Chas. W. Melcher, a gentleman of well-known ability and enterprise. The Lidgerwood Manufacturing Company is one of the busiest and most prosperous concerns in the United States, and have sold over 8,000 of their famous engines.(The Mechanical news, Volume 21)

1892:

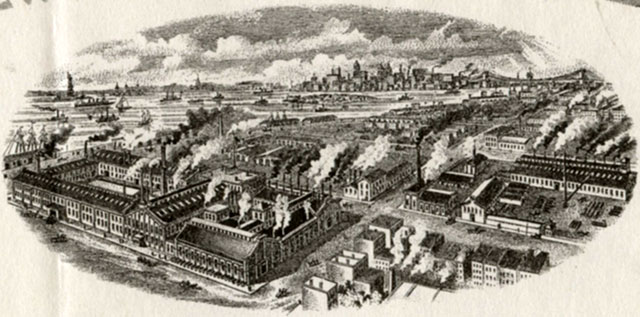

IMPROVEMENT IN BUILDING DAMS. A telegraphic dispatch to the New York Herald, from Austin, Texas, June 7, says regarding a big raise in the Colorado river: "During the terrific storm of fortyeight hours duration, which prevailed west of this town, the Colorado river rose five feet in five minutes, and within three hours it rose twelve feet. In the mountain gorge above the city to-night it is twenty-five feet above low water mark. The big excavation for the foundation of the dam being constructed across the river was flooded and the cofferdam swept away. Many fields are submerged and the loss will be great." This dam is being constructed with a great suspension cableway, which being suspended above the river on towers on a bank the flood did not affect it in the least. Had trestle-work been put in to build this dam it would have been swept away at a great loss to the contractor. The cableway was designed by T. S. Miller, M. E., and furnished by the Lidgerwood Manufacturing Co., 96 Liberty street, New York. It is the largest one ever erected, being 1,350 feet span, 2 inch main cable. Bernard Corrigan is the contractor.Note: No new building for Lidgerwood show up on the 1898 map.LARGE INCREASE OF PLANT. It is always pleasant to tell a tale of progress and prosperity, and the fact that such a happy condition of affairs is deserved, lends additional gratification to the moment. We refer to the exceedingly profitable business already done this year by the Lidgerwood Manufacturing Co., the prominent hoisting engine manufacturers, and to the fact that the largely increased call for their specialties has made it necessary to have still greater manufacturing facilities. To keep abreast of the demand the company have purchased twenty lots opposite their present works, where additional shops, storage houses, etc., will be erected at once. The present works in South Brooklyn, N. Y. cover an entire block, and are conceded to be the finest of their kind in the United States.

(Stone; an Illustrated Magazine, Volume 4)

1897: Ad

Hoisting and Conveying Machinery

LIDGERWOOD MANUFACTURING CO,

Manufacturers of

Improved Hoisting Engines,

Stationary and Marine Boilers for

All Purposes, Cableways

Office and Salesroom

96 Liberty street New YorkGreater New York Representative Business Firms - Fulton NY Old Post Cards

1900: In 1900 the Lidgerwood Cableway "a Hoisting and Conveyance Device" advertised their offices at 96 Liberty street, New York with branches in Chicago, Pittsburgh, Portland, Boston, Philadelphia, Atlanta, Cleveland and London, Eng. and "works" in Brooklyn

The Lidgerwood cableway ... By Lidgerwood Manufacturing Company

LIDGERWOOD TRAVELING CABLEWAY USED IN EXCAVATION OF DRY DOCK AT NEWPORT NEWS, VA.1901: Lidgerwood agreed to a nine hour day for 10 hours wages before their workers went out on strike in 1901.

1902: In August 1902 journeyman blacksmiths and their assistants were on strike at the Lidgerwood and 21 other iron works in or near New York City. There was fear that the blacksmith's, co-workers, the boiler makers would join the strike effectively shutting down all production. It was estimated that 2,000 blacksmiths and helpers were on strike in Brooklyn alone. Boilermakers employed at the Morse firm in Brooklyn earned $2.30 to $3.25 for an eight hour day. Rumor was that the strike would be settled quickly. (BE)

1906: In 1906 Lidgerwood connected to Brooklyn Edison electricity with 520 hp in motors, 100 lamps and 1,000 incandescence. (Electrical world, Volume 49)

1907: In July 1907 the Lidgerwood Society held their 12th annual games at Ulmer Park. Six events included dashes and runs for boys, men and girls.

1910: January, John Hedges Lidgerwood, age 80, vice president and treasurer of the Lidgerwood Manufacturing Company, of 96 Liberty Street New York died at his residence on Speedwell Ave Morristown. The company was said to have plants in Brooklyn and Newark.

1926: Brooklyn Edison Co purchased the main plant of the Lidgerwood Manufacturing Company at the waterfront at Dikeman, Coffey and Ferris streets. The purchase price was reported to have been about $150,000.

1927:

"The area coordinator's assistance was requested by the Federal Traffic Board in the movement of 30 cargo and 3 warping winches from the Erie Basin plant of the Lidgerwood Manufacturing Co., Brooklyn, to the Fleet Corporation warehouse at Hoboken. The total weight of the winches was 220,000 pounds. Army transport lighters handled the winches without cost to the Fleet Corporation."1929: The Lidgerwood Manufacturing Company sold its former boiler shop on Wolcott Street, between Ferris and Conover Streets, to John G. Brown.(Report, Volumes 1-6 By United States. Bureau of the Budget)