Henry Esler & Co, Ship Engine and boiler makers

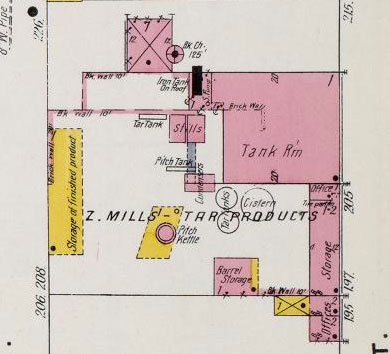

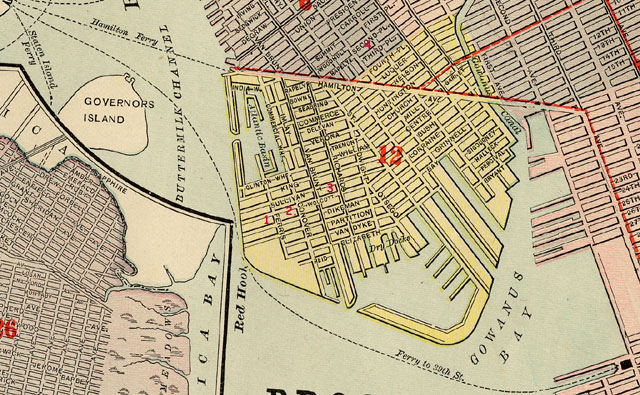

On the 1861 insurance map at the corner of the Southern pier of the Atlantic Basin bordering on King street -

showing a brick building with tin roof, "coped" and including a boiler shop 100x50 feet, smith shop and finishing shop,

coal storage, foundry and an office -

listed as Esler & Co Engine & Boiler Works.

On the 1886 map this building is labeled "oil works".

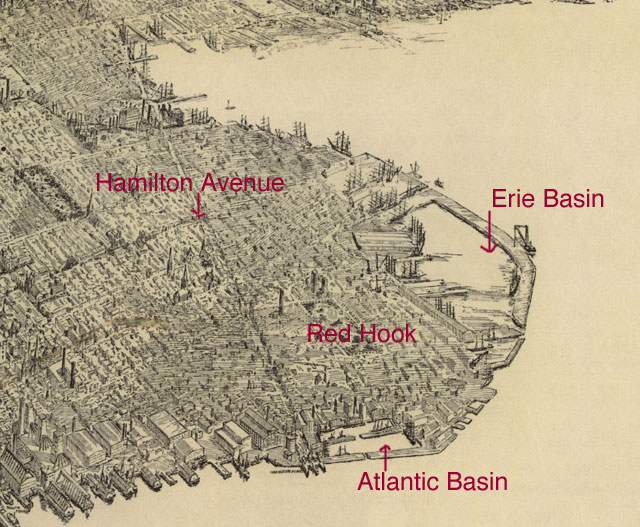

Esler and Company Boiler Factory was located

near the south-western end of the Atlantic Basin.

Henry Esler & Co. built steam engines and boilers. In 1862 they built the machinery

for the steamer Shantung which was built for the "China coast trade"

She is about 1,000 tons burden, of a beautiful model, and

fitted with an overhead beam engine, like that of our river boats.

This engine was an object of great interest to a select party of engineers,

editors and others who were invited, during the outward trip down the bay,

to witness the operations of two different valve motions, with which it had been

fitted, and which were arranged to be changed from one to the other,

to show the effects of each. The engine has a cylinder fifty inches in

diameter, with a stroke of ten feet. It was built by H. Esler & Co.,

Atlantic Dock Works, Brooklyn, and is a substantial and excellent piece of mechanism.

Scientific American, vol 6 1862

The cylinders of the engines on the Shantung had a diameter of 50

inches and the length of the stoke was 11 feet. (A stroke is the action of a

piston travelling the full length of its locomotive cylinder or engine cylinder

in one direction. Wikipedia).

There were two boilers in the hold which did "not use blowers".

Henry Esler & Company also build the machinery for a companion ships the

Steamer Kiang-Tze, the Shan See and the Sze Chuen.

THE SIDE-WHEEL STEAMER KIANG-TSE.

Hull built by Messrs. LAWRENCE & FOULES, Greenpoint, L.I.; machinery constructed by Messrs. HENRY ESLER & Co., Brooklyn; owners, Messrs P.S. FORBES & Co., China; intended service, Coast of China.

Hull -- Length on deck, 200 feet; breadth of beam, 33 feet; depth of hold, 11 feet, 6 inches; draft of water, at load line, 7 feet, 6 inches; tonnage, 1,100 tons; frame is of white oak, chestnut, hacmetac and locust; and has iron straps diagonally and doubly laid, 4 by 1/2 inches, running around it.

Machinery -- Vertical beam engine; one cylinder, 50 inches in diameter, and a stroke of piston of 10 feet. The waterwheels are 28 feet in diameter, and have 26 blades in each; two return flue boilers in vessel.

New York Times April 9 1862

Henry Esler and Co were listed at the Atlantic Docks in 1869 (Congressional serial set: Issue 1388 - Page 21).

Railway age: Volume 18

books.google.com

1886 - Snippet view

This machinist was Henry Esler, who was subsequently proprietor of

shops at the Atlantic Docks, Brooklyn.

Henry Esler died in 1876 and was buried in Green-Wood Cemebery along with is wife Catherine L. (died 1878) and

Mathilda (died 1883) and Gertrude A Eseler (died 1915).

According to the obituary of Henry Hull Tibbals in December 1886, Henry Elser & Co were the proprietors of the

Atlantic Dock Iron Works. It was also called the Atlantic Iron Works in a New

York Times article of June 9, 1863

Eastman & Mandeville Co. Tuna Oil Refinery,

Oil Works, between King street and Clinton Wharf at the Buttermilk Channel

On 1861 map as Esler and Co. Boiler makers. See above.

The 1880 and 1886 maps show a brick structure labeled "oil works" between King street and

Clinton Wharf at the Buttermilk Channel .

Atlases of New York city.

Insurance maps of New York. Brooklyn Atlas 63.

Vol. 1, 1886 shows a brick building labeled Eastman & Manville Co. Tuna Oil Refinery

Rogers Match Factory

Not labeled on the 1869, 1880 or 1886 maps. News articles indicate that it was at the corner of Columbia and Delavan. One article lists it at Richards and Ewen streets.

The NYPL has Brooklyn maps online for 1874 and 1875 but they do not contain details of businesses in the area.

FIRE: April 28, 1869 caused by matches in the drying room - $100 damage. Factory owned by Wm H Rogers corner of Columbia and Delavan.

FIRE: June 10, 1870 caused by matches in the drying room - little damage. Factory owned by William H Rogers corner of Columbia and Delavan.

FIRE: June 16, 1871 caused by boys throwing stones at the building and igniting matches - $1,000 damage. Factory owned by Wm H Rogers corner of Richards and Ewens .

FIRE: May 6, 1872 caused by boys throwing stones at the "patent match factory" and igniting matches - $1,000 damage - no insurance - building owned by Martin Shea. Factory owned by "Willison" Rogers & Co., corner of Columbia and Delavan. In February 1872 Martin Shea owned a liquor store on the corner of "Delevan" and Van brunt.

William Rogers, match manufacturer, was listed in the 1870 Census in Ward 6.

Rogers William H 30 abt 1840 Male White New York,

Rogers Nancy 32 abt 1838 Female White New York,

Rogers Jessie H 6 abt 1864 Female White New York. William H Rogers died in 1876. His widow was listed in the 1880 census: Kimball, Thomas, clerck in store, 80 abt 1800 Self Widower, New Hampshire,

Rogers, Nancie, 37, abt 1843, Daughter, Widowed, New York, New Hampshire,

Rogers, Jesse H., 16, abt 1864, Daughter, Single, New York, on Atlantic Ave.

Directory listings

William H Rogers

Residence Year: 1870

Street Address: 29 Rapelyea

Residence Place: Brooklyn, New York

Occupation: Matches

Publication Title: Brooklyn, New York, City Directory, 1870

William H Rogers

Residence Year: 1871

Residence Place: Brooklyn, New York

Occupation: Match Manf

Publication Title: Brooklyn, New York, City Directory, 1871

William H Rogers Delavan Columbia

Residence Year: 1871

Residence Place: Brooklyn, New York

Publication Title: Brooklyn, New York, City Directory, 1871

William H Rogers

Residence Year: 1872

Street Address: 110 Rapelye

Residence Place: Brooklyn, New York

Occupation: Matches

Publication Title: Brooklyn, New York, City Directory, 1872

William H Rogers

Residence Year: 1873

Street Address: 190 President

Residence Place: Brooklyn, New York

Occupation: Matches

Publication Title: Brooklyn, New York, City Directory, 1873

PATENT, 1868

83.412. - William H. Rogers, New York. N. Y. - Match Composition. - October 27, 1868. - A composition of saltpeter, orris root, minium, phosphorous, and dissolved caoutchouc is used to make the match flexible, self-igniting, and combustible throughout its length.

Claim. - The use of caoutchouc, (or India rubber,) or of gutta percha, in a composition for the manufacture of matches, substantially as and for the purposes described.

(Annual report of the Commissioner of Patents, Volume 2, 1870

PATENT, June 7, 1870

103,931 - FUSE COMPOSITION - William H Rogers, Brooklyn, NY. (no further information).

ROGERS, WILLIAM H. was buied in Greenwood Cemetery 1876-10-10 Lot 6991 Section 48 -

Nancy Kimball Rogers was buried in Greenwood Cemetery 1920-12-04 Lot 6991 Section 48

Phosphorus match production was a simple process.

A splinter of wood was dipped in melted phosphorus (sometimes combined with other chemicals), then covered with

gum or glue and set to dry. The process is hazardous both from the danger of fire

and the danger of phosphorus poisoning.

Willis and Son Match Factory

The Willis & Son match factory was not shown on the 1869, 1880 or 1886 maps on Seabring street.

FIRE: August 29, 1871 A fire in a two story frame building at 57 Seabring street in the William and Son match factory was caused by matches drying in the sun. The business was not insured - damage $1,000. The fire spread to #59 and unoccupied building owned by Francis B Cutting.

"Mr. Cutting" was advertising 2 new buildings on Seabring street 50x50 with 4 lots for $600 in

June 1860.

J. A. H. Bell Paint Mill - on Columbia between Luquer and Nelson Streets

The 1869 map lists J. A. H. Bell Paint Mill on Columbia between Luquer and Nelson Streets. There is nothing listed and no building indicated at this location on the 1880 and 1886 maps.

James A H. Bell was raised by his "uncle" Augustus Bell. Both had some connection to white lead paint manufacturing in Brooklyn although it was not the main occupation of either of them. Both were also major philanthropists - giving generously of their money and personal collections to a variety of Brooklyn Institutions.

Augustus Graham was born Richard John King in Modbury, Devon, England in 1776.

At some point Richard King changed his name to Augustus Graham. Around 1808 he formed a partnership with John Bell, who changed his name to John Graham.

They founded the Brooklyn White Lead company in 1822.

Their business was located at Front Street between Washington and Adams. They suffered a disastrous fire in the fall of 1864. However, they quickly bounced back and

introduced measures to

extinguish future fires. Augustus Graham married Martha Cocke. They had at least one daughter, Eliza Rebecca, born in Frederick Maryland in 1808. She married Chester Coleman. The 1850 census in Brooklyn listed Augustus Graham 75,

Chester Coleman 49,

Elizabeth R Coleman 42,

Augustus G Coleman 14,

Louisa A Coleman 16,

and two servants.

Augustus Graham died November 27, 1851. John Bell Graham died March 11, 1853 at 37 Sands Street.

Pure white lead has the reputation of being the best paint in respect of color and body. It is also used in the preparation of vulcanized caoutchouc. The preparation of the pure white lead requires the use of the purest metallic lead; and that preferred is either European lead that has been refined, or the metal from the upper mines of the Mississippi. The old method was to use the metal in thin sheets, cut in small pieces, each of which was rolled into a loose spiral, in which form it could be conveniently subjected to the action of the vapors by which its conversion into carbonate is effected. Instead of these spirals the metal, after the invention of Mr. Augustus Graham of Brooklyn, N. Y., is now almost universally cast in the form of gratings or "buckles,"

so called from their resemblance to the large shoe buckles of former times.

(The new American encyclopedia: a popular dictionary of general ..., Volume 16

edited by George Ripley, Charles Anderson Dana, 1869 and several others)

James A. H. Bell was born circa 1815 in New Orleans. Ophaned at an early age he was raised by Augustus Graham and John Bell Graham.

James A. H. Bell was a book and art collector who lived on Sands street and gave most of his collection to various Brooklyn institutions, notable the Brooklyn Public Library and

the Brooklyn Museum.

Graham and Bell

1846

J. A. H. Bell supplier of Paints &c. to 10th June 1846 (Proceedings of the Board of Assistant Aldermen, Volume 28

By New York (N.Y.). Board of Assistant Aldermen)

1850

Augustus Graham

Residence Date: 1850

Residence Place: Brooklyn, Kings, New York, United States

Comments: White lead manufacturer

1850 Census Augustus Graham age 75 white lead manufacture born Scotland 2nd ward, Brooklyn.

Ward # Brooklyn, James A. H. Bell, merchant 31,

Lucretia N Bell 25,

John G Bell 4,

Charles A Bell 2,

Richard H Frost 21,

Royal Payne 42,

Elizabeth Payne 36,

Grace Maloy 18,

Mary Donagan 17. John and Charles were in boarding school in Queens in 1860.

1854

"J. A. H. Bell, New York, exhibited a case of Paris greens in powder and mixed, and some American vermilion (sub-chromate of lead) ; colours all good."

(Professor Wilson's special report,The New York Industrial Exhibition 1854

Parliamentary papers, Volume 36

By Great Britain. Parliament. House of Commons)

1856-1861

J. A. H. Bell was an officer of the Nassau Fire Insurance Company of Brooklyn in 1856 and 1861.

1863 J. A. H. Bell of Brooklyn had 30 shares valued at 3,000 in the Croton Fire Insurance Co.

1869

J. A. H. Bell Paint Mill was listed on the 1869 map of Brooklyn at Delevan and Commerce on the east side of Columbia.

1870 Census

J. A. Bell, retired merchant 5th ave between 29th and 30th street.

1898

A gift of 10,425V., rich in travel, history, biography, and theology, have been given the Brooklyn public library by J. A. H. Bell. The books represent the collection of a lifetime by Mr Bell, who is eighty-two years old. The books represent a value of $100,000.

Public libraries, Volume 3)

1898

"In the latter part of 1898, the bequest of Mr. J. A. H. Bell, gave the gallery four pictures of distinct value, by Boucher, Fyt, Clays and Jan Wyck, and some others of minor importance"

The annual report of the Brooklyn Museums

By Brooklyn Museum, Brooklyn Institute of Arts and Sciences. Children's Museum. 1904

1898

"

Nearly 11,000 Volumes Presented to Brooklyn Institutions by James A. H. Bell. James A. H. Bell sat In the dining room of his home at 45 Sands Street, Brooklyn, one day last week, and watched the men fill the furniture van with the last of his.......

of especial interest, because he is a relative of the founder of the institute, Augustus Graham, who, it will be remembered, (New York times book review and magazine - Page 455, 1898)

1899

Donations of Paintings to the Department have been made during the year as follows :

From Mr. J. A. H. BELL:

"Visit to Grandpa," by CHARLES NAHL.

" Niagara Falls," by J. F. CROPSEY.

"The Merrymakers."

"Preparing for a Feast," by GEORGE ARMFIELD.

"The Mourners," by GEORGE ARMFIELD.

"A Flower Seller of Seville," by GEORGE H. HALL.

"Portrait of John Graham", by CHARLES NAHL.

"Portrait of Mrs. John Graham", by CHARLES NAHL.

"Marine View," by P. J. CLAYS.

"Unconscious Innocence," by F. BOUCHER.

"Still Life," by JAN FY'l.

"Pastoral Scene," by FRAIES.

"Hawking Party."

"Street Market at Night," (a) by CULYERHOUSE.

"Street Market at Night," (b) by CULYERHOUSE.

"Street Market at Night," (c) by CULVERHOUSE.

"Woodcock," by HOLBURTON.

"The Lovers," by CONSTANTIN BOON.

"Pastoral Scene," by DESON.

"The Bathers," by THALLMAN.

"Portia and Narissa," by BROCKMAN.

"Miniature on Ivory, Girl."

"Miniature on Ivory, Grandmother."

"Crucifixion."

Yearbook of the Brooklyn Institute, Volume 11

By Brooklyn Institute of Arts and Sciences, 1899

DEATH: February 2, 1901

"JAMES A.H. BELL DEAD.; The "Monte Cristo of Brooklyn" Passes Away at 84 -- Gave 10,400 Volumes to Brooklyn Library.

James A.H. Bell, best known to residents of Brooklyn through the gift of his library containing 10,400 volumes to the Brooklyn Library in June, 1898, died yesterday from the grip, at his home, 45 Sands Street, Brooklyn, in his eighty-fourth year. Mr. Bell had been ill for about fourteen weeks."

NYT

James A. H. Bell was born in New Orleans. He was orphaned when his parents died of yellow fever. He came north at the age of four to live with an uncle, Augustus Graham, who lived on Clinton Street in Brooklyn. Bell lived at 45 Sands Street in Brooklyn for most of his life. He was a very wealthy man having made a fortune in his own right and also having inherited from his uncle. He had two sons from his marriage. One was still living at the time of his death. He was also survived by four grandchildren and a great grandchild. He was buried in Greenwood Cemetery which also contained the garve of his wife.

"Mr Bell established the first white lead factory that was built in Brooklyn.

It is well known that after the establishment was going well Mr. Bell went to Europe, leaving his two sons in charge. During his absence the business came to an end." John G and Charles A Bell were listed in Brooklyn Directories in 1868 and 1871 as "paints".

(BE February 04, 1901)

His sons, John G and Charles A Bell died "since the execution of the will" so his property went to his housekeeper and his grand children and to the Brooklyn Public Library. (BE February 8, 1901). Charles Bell age 52 died in Kings County Dec. 2, 1900.

White Lead

White lead is a toxic chemical compound formerly used in "lead" paint. It has been outlawed in most countries.

Augustus Graham

Paint Factory

There was a fire in 1869 at the Jessup and Childs Paint factory on Summit Street. They were located on the north side of Hamilton Avenue.

DeMars Overalls

R. H. DeMars manufactured overalls at 399 Van Brunt street.

See DeMars

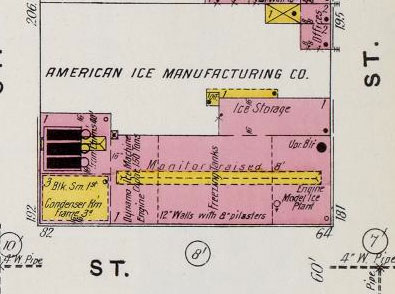

Iron Works between Van Dyke and Elizabeth streets at Dwight

The 1886 map shows an Iron Works between Van Dyke and Elizabeth streets at Dwight

Car Depot between Van Dyke and Partition streets at Richards

The 1886 map shows a Car Depot between Van Dyke and Partition streets at Richards

Iron Works

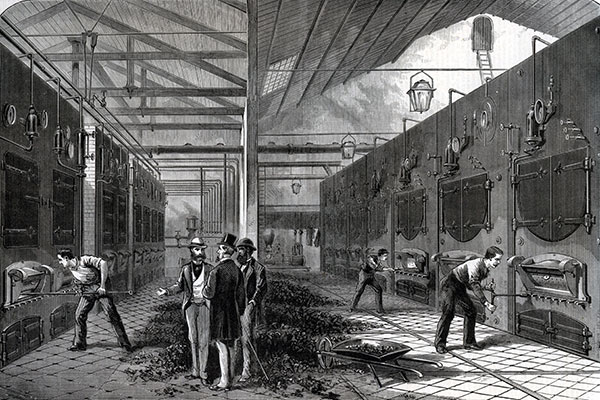

Perhaps the most common industries in Red Hook in the mid to late 1800s were "iron works" -

manufactures of large

machinery such as boiler makers, hydraulic pumps, steam rollers,

ship parts, stoves, etc. These were companies that incorporated foundries as part of the manufacturing process.

These businesses had several things in common including the types of employees which included:

boiler makers, riveters,

draftsmen, pattern makers, blacksmiths,

machinists,

molders, foundry workers, superintendents, foremen,

salesmen, sales manager, general managers, purchasing agents, and traffic managers.

As well as common laborers who fetched and carried.

Puddlers, rollers, molders, and heaters where categories of skilled iron workers.

The "works" included: offices, drafting rooms, blacksmith shops, forges, foundries, production sheds,

machine shops, erecting shops, powerhouses, chimneys, and pattern storage areas.

In 1899 there was an ironworkers strike in Red Hook. The strike was confined to union members

who were demanding shorter hours. The asked for a scale of an eight hour day on "old" work and a nine hour day on

"new" work. Non striking members were working

"on a scale of nine hours a day". Riveters were getting $2.80 a day. Heaters [?] were getting

$1.50 a day. The competition was working a ten hour day for less pay.

Ten years earlier in January 1889 Pittsburgh Iron workers went out on strike agains reduction in wages:

Puddlers from $4.00 to $3.50 per ton

Boilers from 6.00 to $5.0 per ton

Refiners from 1.00 to .40 per ton

Scrappers for 3.75 to 2.50 per ton

Heaters from 1.37 to 1,00 per ton

(Congressional Serial Set, 1889)

Another take on 1889 wages indicated:

In the Tudor Iron-works are three hundred and thirty men. One bar mill roller makes $8.13 a day;

three guide mill rollers make $6.50; four bar mill heaters make $7; six guide mill heaters make $5.25;

six puddlers get $4.66, and ten puddlerhelpers $2.50. Thirty skilled iron-workers average $4.66 a day.

The other three hundred employes, or ninety per cent. of the entire force, earn $1.75 a day.

"One thing to be remembered," said Mr. M , "is that

though our wages are high they are not steady. For a long time four months a year was

considered a good average. Even now the average does not exceed six months in the year.

This is because with the least degree of prosperity so many rush into the

business, and wages fall. .....

A good puddler can puddle three thousand pounds a day. ....

Molders (another class of iron-workers) are not paid as well as bar mill rollers.

(The Tramp at Home, Lee Meriwether, 1889)

By 1893 machinery was replacing many iron workers jobs.

Puddlers

The puddler (or boiler) was a skilled iron worker. With his helpers, the puddler used a furnace to

remove impurities

and convert pig iron into

semifinished iron bars from which the machine shop manufactured finished goods.

Heaters

The iron produced by the puddler was sent to the heater to be reheated before shaping.

Due to the high temperatures to which they was exposed a heater and his helpers needed frequent rests.

Pattern makers

Pattern makers produced precise wooden or cast iron patterns of the parts to be produced.

Moulders

Moulders used a special blend of molding sand and water which was tightly packed around the wooden mold.

There was a delicate balance

between packing the sand too hard, too soft, too much water, not enough water, etc.

From this sand pack the moulder would cast a mold into which the molten iron would be pored forming

the desired part.

Moulding required a through knowledge of the properties of the

metal as well as the technically ability to

properly mix and pack the sand.

See You Tube for a 1924 version of mold making.

Machinists

Machinists finished the parts produced in the foundry.

This work also required a high level of skill and knowledge.

They made cuts, and used files and scrappers to highly finish the part so it would fit properly

in the machine under construction.

Pattern making and molding were the most highly skilled

workers in the foundry. Puddlers, heaters, pattern makers, moulders and machinists

were considered craftsmen.

Boiler Makers

On July 20, 1901 the Brotherhood of Boiler Makers and Iron Ship Builders of South Brooklyn Lodge No 171

gave their sixth annual picnic at the Old Iron Pier at Coney Island.

Iron Workers - The Tramp at Home - Lee Meriwether

The Ironworker's Noontime - Thomas Anshutz - 1880

|