Photo by E Ineson Batley from Views and Reviews , 1896 courtesy of the Batley Community Archives, May 2006

| Shoddy - New Fabric From Recycled Wool |

| HOME - Land Introduction - Benjamin Law - Connections to All Law Pages |

|

Benjamin Law and the Development of Shoddy Circa 1813 in Batley, England, Benjamin Law developed a process using recycled woolen rag combined with virgin wool to make a material called shoddy. Benjamin Law is listed as the developer of this process in several books on the woolen industry in Yorkshire and is recognized by the city of Batley in a commemorative plaque. A Guide to Batley at A Guide To Batley states: "Batley's heritage can be traced back to the start of the Industrial revolution when Benjamin Law, a local man, decided to mix finely shredded rags with virgin wool to produce woven cloth known as "Shoddy", which had a revolutionary effect on the textile industry."Occasionally Benjamin's brother-in-law, Benjamin Parr, and/or his son, also Benjamin Parr, are given credit. The consensus seems to be that the first mill to produce shoddy was in an area of Batley called Benny Parr Woods. It is unclear if the area was named for Benny Parr senior or junior. The area south west of Leeds had been a major center of woolen cloth production for centuries. Several types of cloth were woven from wool. "Woolens" were heavy felted cloths of the type used for coats and blankets. The cloth trade in England suffered during the the Napoleonic War because of trade embargoes. However, the woolen trade in West Yorkshire remained relatively strong. One of the major problems in the woolen trade in the early 1800's was the lack of sufficient yarn to meet the demands of all the weavers. England did not produce enough wool itself and the war restricted the amounts of importable wool. In the time before the Industrial Revelation much more time and many more people were needed to prepare and spin the yarn than were needed to weave the cloth. Spinning was a time consuming activity. On the other hand the weaving went relatively quickly. The word "spinster" (to denote someone who never married) is a reflection of the need to have people who had virtually no life except spinning in order to provide the family with enough yarn to keep the family clothed. Spinning wheels greatly speeded up this process, but it still required more spinners than weavers. With the advent of carding and spinning machines the process was accelerated to the point that spinning could more than keep up with weaving. The cloth industry grew at a rapid rate after the introduction of carding and spinning machines. The increased demands for cloth created a need for more raw materials and out of this need shoddy was born. Benjamin Law developed a process of turning recycled old rags mixed with some virgin wool into shoddy around 1813. He was unable at the time to figure out a way of incorperating taylors clippings into the process. This was figured out by his nephews several years later and was called "mungo". By 1855, 35,000,000 pounds of rag were being sorted and processed into yarn to make "mungo" and "shoddy". The making of shoddy and mungo is a similar process to the making of woolen and worsted, once the rags had been ground up and processed into yarn. Batley and Dewsbury were the major centers for the rag collecting and sorting business, as well as the manufacturer of shoddy and mungo. Rags were collected from two sources.

Old rags were not as valuable, as they were dirty and needed more processing to turn into yarn. New rag was used for mungo, which was a finer cloth than shoddy. Mungo was developed by Benjamin Law's nephews, who were the sons of his partner, Benjamin Parr, and Parr's wife, Elizabeth Sheard (The sister of Benjamin Law's wife, Lydia Sheard.) The sorting of the rag was done at the rag merchant's establishment. The work was mostly done by girls and women. The sorting was done in large well-lit rooms over tables with "riddles" (basically a wire mesh to allow the dirt and dust to fall through). Baskets were placed all around the worker, who sorted the rag to the baskets by quality and color. Sorting was skilled labor. Rag sorters had to recognize the difference in quality of the rag in mixed lots both accurately and quickly. A smart rag sorter could sort about one cubic weight of old rags in one hour. New rag took longer, because it required greater care due to its higher value. Only woolen and worsted were used to make shoddy and mungo. Cotton rag was used to make paper. Sir George Head wrote: "The trade or occupation of the late owner, his life and habits, or the filthiness and antiquity of the garment itself, oppose no bar to this wonderful regeneration; whether from the scarecrow or the gibbet, it makes no difference; so that, according to the change of human affairs, it no doubt frequently does happen, without figure of speech or metaphor, that the identical garment to-day exposed to the sun and rain of a Kentish cherry orchard or saturated with tobacco smoke on the back of a beggar in a pothouse, is doomed in its turn to grace the swelling collar, or add dignified proportion to the chest of the dandy".And again from Mr Taits book: "Hither are brought tatters from pediculous Poland, from the Gipsies of Hungary, from the beggars and scarecrows of Germany, from the frowsy peasants of Muscovy; to say nothing of snips and sherds from monks' gowns and lawyers' robes, from postillions' jackets and soldiers' uniforms, from maidens' bodices and noblemens' cloaks" A heterogenous collection truly, to be shredded by "devils" into mungo fibre, re-spun and re-woven, and thus resurrectioned into new material for the backs of people who little dream of the various vicissitudes through which their garments have previously gone."Shoddy has come to mean something made with inferior material. However, the development of shoddy in 1813 was of financial significance in the woolen trade in Yorkshire in the 1800's and later. Batley became the center of shoddy manufacturing in England and was still the center of the shoddy trade as late as World War I. Shoddy Grinding Mill, 1862 John Hewitt in the History and Topography of the Parish of Wakefield and its environs published 1862 gives a description of the Shoddy Grinding Mill as follows: "About the years 1829 and 1830, I recollected a man of the name Pearson, who was a manufacturer of flocks, at East-Moor, Wakefield. He had a grinding machine which was worked by hand labour, and with this machine he ground woolen rags, commonly called "hard woolens" (old cloth garments) into flocks. This grinding mill was very much like the apparatus fixed at the head of a draw well, for the purpose of drawing up water, with the exception that the roller, instead of having a rope attached to it, had many iron-spikes or teeth well sharpened fixed in it; and, in lieu of the well, there was a large wooden box, into which dropped the rags which had been speedily rent or torn into flocks by the iron teeth of the roller, when motion was given to the latter by means of turning round the crank attached to it. Flocks thus ground much resemble wool, the originals fabric of which woolen cloth is made, but being of course the "worse for wear" and in consequence of the pulling to pieces by the mill, are of a much shorter nature, or fibre, than the new wool is; but notwithstanding this drawback, woollen rags disentangled in this manner by mills, similar in principle to the one I have mentioned, have become a famous article of traffic in Dewsbury, Ossett, Daw-Green, Horbury, Wakefield, and a few adjacent places westward from Wakefield. With the admixture of a little new wool, the flocks (called "shoddy") produced by grinding "soft woolens" (old stuff garments, flannels, etc.) have become extensively used at Dewsbury and a few neighboring places, and are manufactured into "new cloth" and other kinds of new woollen goods, suitable to be made into new wearing apparel! Invention and the skill of man are always progressing; and in course of time it was discovered that cloth rags (hard woolens) when properly separated from sewing thread and cotton linings, were much superior than soft woolens in being made up into new cloth, and this caused them to much exceed the latter in price as 3d. and 4d. per stone of 16lbs*, whilst, since their improved value, I have known old cloth rages devoid of seams, and likewise new cloth "clippings" (tailors rags) sold at as much per lb.. There is one fact with regard to woollen rags, which, more than any other is calculated to make a person smile who is unacquainted with their history in this part of the West-Riding. This fact is that woolen rags, especially hard woolens, have frequently in large quantities, used as manure for potatoes, and when the new potatoes were gathered; and, after the latter's going through the process of grinding by the shoddy mill , (laconically, humorously, and justly styled "the Devil"!) they have been re-manufactured into "bran-new cloth". I can vouch for this; for I have seen potatoes manured with woolen rags in Wakefield, and which same rags were afterwards sold at a good price for manufacturing purposes to the shoddy manufactures of Dewsbury!*In May 2010 David Pimplett expresed suprise at the "stone of 16 lbs" and wondered if this was a mistake or were the normally parsimonious members of the waste trade being generous. Since I known nothing of stones and English pounds I asked for more information on what was so surprising about this particular "16 pound stone". David replied: The old British weight system had 16 ounces in a pound ( 16oz per lb) and 14 lbs in a stone and 8 stones in a hundred weight (cwt ) a cwt was actually 112lbs, and 20 cwts in a ton (2240 lbs. I know that it was complicated but it worked for 1000 years." The problem is I am not sure if that was what was written or if I made a typo. I am pretty sure that I found this book on microfilm at a library that is now closed. I was not able to find The history and topography of the parish of Wakefield and its environs By John Hewitt on line as of August 2014. Shoddy Manufacturers in Batley In 1822, nine years after Benjamin's invention, the Baine's Directory (like a phone book before telephones) for the town of Batley listed Benjamin Law as a "Flushing Manufacturer" under the heading "Professions and Trades". (Information about the Baine's Directory was taken from BATLEY in Baines's Directory and Gazetteer Directory of 1822) Flushing and shoddy may have been the same thing because the only definition of flushing I could find described it as "a course heavy woolen fabric" and noted that it was the type used in military uniforms. Baine's Directory lists 118 people, including four women, involved a trade or profession in Batley. There are 25 people listed under "Miscellany of Trades" including the schoolmaster, the parish clerk, a mill owner, a "bone setter", and the four women. Two of the women are listed as "vict." (This may stand of victualer) at what appear to be taverns or pubs. The other two women are listed by their names only, no occupation or trade is listed. There are separate categories listing, 30 blanket makers, 4 butchers, 4 carpenters, 4 cattle dealers, four coverlet manufactures, the 21 flushing Manufacturers, 3 grocers, 2 maltsters, 3 stone masons, 2 surgeons, and 16 woolen manufacturers. There were two Michael Sheards, both flushing manufacturers. The Sheards were shoddy manufacturers for many years. Michael Sheard and sons are listed in all the directories as shoddy manufactures through the 1870s. Benjamin Law's second wife was Lydia Sheard, the daughter of Michael Sheard. It was the sons and grandsons of Michael Sheard's brother, George Sheard, who made their furtunes in shoddy. Many people made a lot of money on shoddy. However, Benjamin Law and his children did not seem to turn Benjamin's invention into the financially successful venture that other did. Leeds directories for 1830, 1834, 1842, 1861,1863 and 1863 included very few listings for the Law family:

The censuses in Batley indicate that the descendants of Benjamin were not among the manufacturers of shoddy. Benjamin's children, George, Joseph, William, Abraham and Isaak were listed in the censuses in Batley

Another family member who were involved with the shoddy trade was Robert Walker Sykes, the brother of Elizabeth Sykes who was listed in the 1881 census as a rag grinder. His father-in-law, James Hepworth, was listed as a rag merchant. 1840s Shoddy did not meet with universal approval. There were those who feared the demise of the English woolen trade because of the adulteration of virgin wool. Some claimed that shoddy did not make a better fiber only a cheaper one. Others complained that the manufacturer could substitute shoddy for real woolen fabric thus cheating the customer. It was called a wolf in sheep's clothing. Some like William Busfield Ferrand (1809-1889), called it the Devils Dust because it was claimed that the process produced enormous amounts of dust using a machine called a devil. William Busfield Ferrand M. P., a conservative politician, demonstrated his contempt for shoddy on March 12, 1842 by tearing a piece of the material to shreds in front of the entire House of Parliament. The History of the Shoddy Trade: Its Rise, Progress, and Present Condition By Samuel JUBB stated: "In the year 1840........1859 Journal of the Royal Statistical Society, Volume 22 The place where shoddy was first used in this manner was Batley, by Mr. Benjamin Law, and the first machines for tearing up the rags were set up by Messrs. Joseph Jubb and J. and P. Fox. The manufacture has forced its way, and made Batley, Dewsbury, and the neighbourhood the most prosperous parts of the woollen district. There are now in Batley alone fifty rag-engines in thirty-five mills, producing no less than 12,000,000 lbs. of rag-wool per annum (after deducting for loss of weight in the manufacture); and I am assured, on good authority, that three times this quantity is made in the district. The rags are gathered from all parts of the kingdom, as well as imported regularly from the continent, America, and Australia. There is now a considerable manufacture of the shoddy, or rag-wool, in Germany, and it is believed that no less than 9,000,000 or 10,000,000 lbs. weight was imported last year.1874 Report of the Annual Meeting, Volume 45, Part 1874 By British Association for the Advancement of Science. Meeting On the Shoddy Trade. By Samuel Jubb. In his 1858 book on the History of Batley Samuel Jubb did not acknowledge Benjamin Law as the person who developed shoddy. See Batley |

| Great industries of Great Britain By Great

Britain, 1884

"So far as we know, there is no direct evidence as to the person who first ground or tore up woollen rags, and it is equally unknown at what precise date the operation was first undertaken. Probably many enterprising persons tried what they could make out of woollen rags, and not having succeeded, ceased further endeavours. What we do know is, if meagre, at least authentic. Some few furniture manufacturers-chiefly makers of bedding, mattresses, and stuffed furniture, in and around London, the chief seat of the paper manufacture of this country-and a few saddlers in the metropolis itself, used larger or smaller quantities of woollen "flocks" to mix with hair and other materials in their business. But up to the year 1813, nobody ever thought of applying the product to the cloth trade, until a Yorkshire manufacturer, merely by accident, saw a saddler employing it to stuff a piece of harness. The manufacturer referred to was Mr. Benjamin Law, who carried on business in Batley. Having occasion while in London to call upon a sadoJer, he saw one of the workmen using a material, totally new to him, of a long, woolly fibre resembling the material with which he was so familiar. On taking a handful from the heap to examine it, he found it really was wool, and he was led to ask a few questions as to where it came from and who manufactured it. He learned to his surprise that it was the outcome of old stockings, hosiery, or blankets. He thought it was capable of being spun, and, with the view of trying the experiment, sent an order to the person who sold it, and upon mixing it with a small percentage of new wool, wove it into a piece of cloth. This was in the year 1813. Mr. Law found a ready sale for his new product, at once invested the whole of his capital in the enterprise to which he had been led by a chance visit, and became the founder of the shoddy trade. Mr. Law was a native of Great Gomersal, a village near Bradford, and was born in the year 1772. Finding that he could produce more than he could dispose of in the English market, he sent his son John with a large consignment of goods to America, where he met with a ready sale at a good profit. A second venture in the same direction was agreed upon, and into this the original shoddy manufacturer put all his energy and all his money. His son started, no doubt with high hopes of success, and Mr. Law himself, in all likelihood, looked forward to securing the means of extending his business. Weeks passed away, but Mr. Law heard nothing of his son; and at length, fearing that he had died, or that some accident had happened which prevented his writing, determined to go out in search of the young man and his precious freight. He went to America, sought high and low, but no trace of his son or the goods could be found, and he returned home comparatively a ruined man. He died in Stockport in 1837, and was buried in the churchyard of Batley. But the trade once started, many were willing to carry it on, and the result is that a large and continually increasing population has been drawn to Batley and the neighbouring villages, which are chiefly engaged in the shoddy manufacture." |

| Spons' encyclopaeia of the industrial arts, manufactures, and commercial ... By Edward Spon, Francis N. Spon, 1882

"Shoddy. - This includes those recovered wools obtained by pulling into their original fibrous condition all descriptions of worsted and woollen fabrics known amongst dealers as "softs ": that is, unmilled fabrics, such as old blankets, flannels, worn-out hosiery. It is difficult to decide to which amongst the several claimants to the invention of this system the credit is justly due. In Yorkshire, it is usually divided between, or rather claimed for, two persons, Benjamin Purr, of Batley, and Benjamin Law. An enthusiastic inquirer, who has devoted considerable time to the investigation, has, however, been led to the conclusion that the world is indebted to a Jew secondhand-clothes dealer in London, during the Peninsular War, when the stoppage of the supply of Spanish wool, and the brisk demand for army goods for the contemplated expedition to Spain (wool from Spain being then used for making them), drove wool to a great price. This man conceived that it would be a paying speculation to tear up old blankets and white flannels by curry-combs, and mix the product with the genuine wool that could be bought in the London market. This was done, and these "doctored" or adulterated bales were sold in Yorkshire for full prices, yielding a handsome profit to the operator. When this outlet for disposing of the product was closed by the decline in the value of wool, the maker offered it in competition with genuine wool for saddlery and upholstery purposes. This inventor's name is not satisfactorily known, but is conjectured to be Davis. The second progressive step in the utilization of this material (its adaptation to the manufacture of cloth) belongs to the above-named Benjamin Law, a small farmer and weaver of Batley, then an inconsiderable moorland village in Yorkshire. Not satisfied with the prices realized for his webs in Leeds, he extended his ventures to London. Being in the city on one occasion, he observed in a saddler's window some material apparently like white wool, but which differed in several respects from any with which he was acquainted. Getting permission to examine it, he found by testing its staple that it would fully answer his requirements. He found the manufacturer and purchased a parcel for himself, which he sent down to Batley, and fully satisfied himself that it was capable of being transformed into useful fabrics. He carefully guarded his secret, admitting only his brother-in-law, the Benjamin Parr before named, to a knowledge of Ids discovery. These two, having developed the manufacture to some extent, commenced to make the raw material themselves. From this small beginning, after struggling through many difficulties, its use has spread into almost every portion of the woollen manufacture of this and other countries." |

|

All the year round: a weekly journal, Volume 5; Volume 25 By Charles Dickens

THE CITY OF HONEST IMPOSTURE. [April 8,1871.] 441

THE CITY OF HONEST IMPOSTURE. |

| 1880 Article about Benjamin

Law written by his grandson, Edwin Law

Wendy Rose transcribed the 1880 article by Edwin Law and the letters related to it.

For the complete transcription of the Batley Reporter Articles of 1880 go to Wendy Rose

|

|

|

Benny Parr Wood and the Howley Mill Photo by E Ineson Batley from Views and Reviews , 1896 courtesy of the Batley Community Archives, May 2006 |

| | |

|

Benny Parr Wood "Benny" Parr was the brother-in-law and partner of of Benjamin Law. Benjamin Law's second wife was Lydia Sheard. Lydia's sister, Elizabeth, married Benjamin Parr. Benjamin Parr and Elizabeth sheard also had a son named Benjamin Parr. I do not know who the woods were named after - the father or the son. 1912 postcard |

| Postcard collection of Maggie Land Blanck

Canadian Textile Journal vol 37 published in 1920 stated: "Howley Ruins mark the place where tradition say that shoddy first was made, and that a small place in the immediate vicinity is still called "Benny Parr Wood". This is supposed to commemorate the name of the man, Mr. Benjamin Parr, who first succeeded in reducing cloth to fibre." From the very beginning the opposition to the new trade was fierce and long continued. At one time shoddy was widely known as "Devil's Dust," the name invented by a person who laboured with much zeal, much ignorance, and, fortunately, with entire futility, to destroy the growing trade of Batley and its neighbourhood. Economic laws were working then, as they are now, and in spite of Mr. Ferrand, the Batley district is now being supplied with rags from every part of the civilized world - and from some parts we regard as uncivilised."See Images Batley

| |

| | |

|

| Collection Maggie Land Blanck Frank Townend and Sons Shoddy Mill, Batley |

|

|

Collection of Maggie Land Blanck Geo. Gerry & Son, Athol, Mass is still listed in Athol, Mass. as a machine shop.

|

| |

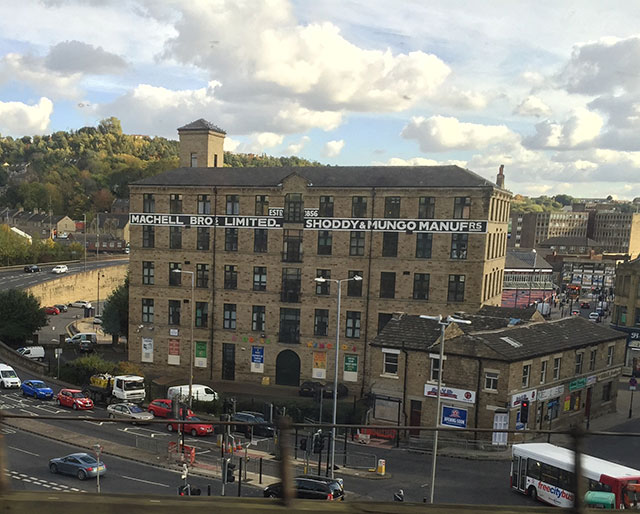

| 1874 Shoddy and Mungo Mill - Dewsbury, Yorkshire - image shared

by Iain Hill, October 2015 The Machall Brothers, Robert Fletcher Macahll and William, established their business in 1856. Robert Machell was married by the 1861 census. His brother, William age 22 was living with the family Under the Hill, Earlsheaton, in Soothill. They were listed as rag merchants. In 1871 Robert Fletcher Machell still in Soot Hill as a shoddy merchant employing 38 hands

Robert F. Machell age 47 was listed in the 1881 census in Dewsbury as a shoddy

manufacturer employing 108 hands. Robert and his wife, Emma lived at 33 Springfield Terrace with their 4 daughters daughters, Mary A. age 23,

Ann age 19, Louisa age 16, Gertrude age 9 and son, Robert H age 5 plus a servant.

|

| Shoddy Manufacturing in the United States

As the trade progressed several Batley shoddy makers

moved to the United States and opened shoddy mills.

Thanks to Elizabeth Gardiner for sharing a very interesting 1906

article on shoddy manufacturing in

the US. Go to

The Technology Quarterly, Volume XIX MIT, 1906

Shoddy mills were also in operation in Germany.

|

| If you have any suggestions, corrections, information, copies of documents, or photos that you would like to share with this page, please contact me at maggie@maggieblanck.com |

| RETURN TO TOP OF PAGE |

| Benjamin Law |

| Photos of Batley |

| Please feel free to link to this web page. You may use images on this web page provided that you give proper acknowledgement to this web page and include the same acknowledgments that I have made to the provenance of the image. Please be judicious. Please don't use all the images. You may quote up my original text from this web page and use any cited quotes on this web page provided you give proper acknowledgement to this web page and include the same acknowledgments that I have made to the provenance of the information. Please do not cut and paste the whole page. You may NOT make use any of the images or information on this web page for your personal profit. You may NOT claim any content of this web page as your original idea. Thanks, Maggie |

| ©Maggie Land Blanck - page created 2004 - latest update, November 2015 |